Metal Injection Molding (MIM) is a near net forming process suitable for the production of small, three-dimensional complex shapes and products with special performance requirements.

As an injection molding technology for manufacturing high quality precision parts, MIM technology has the superiority that conventional powder metallurgy machining and precision casting methods cannot match.

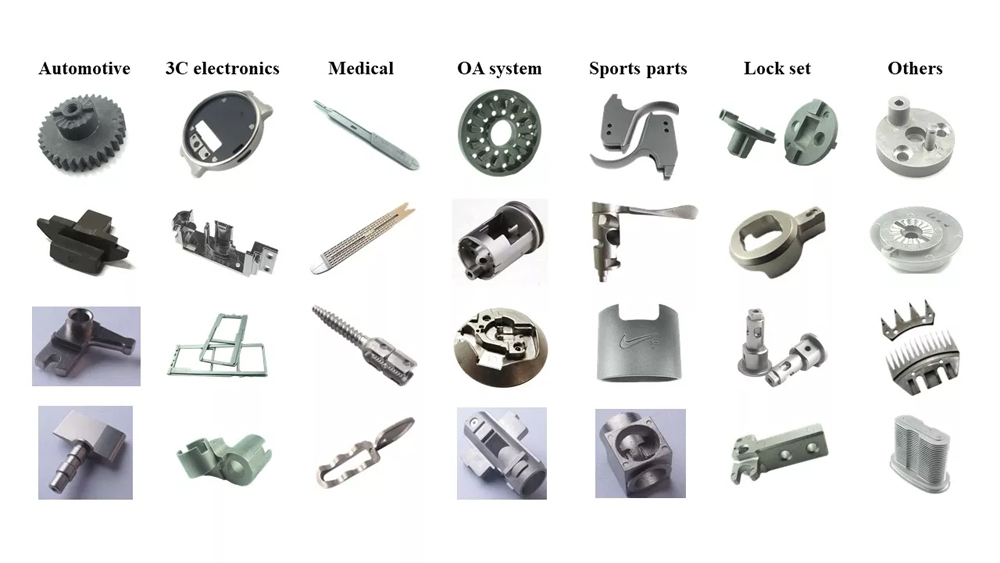

As the fifth generation metal forming technology, MIM has the characteristics of high volume and high efficiency in forming parts with complex shapes, so it is widely used in electronic 3C, automotive parts, medical devices, industrial equipment and daily necessities.

Automotive Parts

MIM has the largest application in auto parts manufacturers, and there are relatively few MIM companies doing auto parts worldwide, but MIM has great potential for application in automobiles.

Common applications are: ignition control lock parts, turbocharger rotor, valve guide parts, automotive brake unit parts, automotive sunshade parts, clutch inner ring, fork sets, distributor sets, automotive conduits, etc.

Main materials and applications for MIM:

Properties of MIM materials

Application of MIM Products

Company Advantage

Independent R&D team, professional production and sales team, great production capacity sustainable supply. Use the best material and production process.

1,Quality policy:

Zero defecets, doing things to be best in one time

Keeping improve and never stop pursuing perfect attitde

reducing cost, and contine improve the compition of products

2, Quality goal:

quality rate can achieve 98%

quality rate of half-finished products is 99%

the failure cost is <2%

3,Our all of products are suit ROHS standard, green parts, without any pollution.

FAQ

1.How to get a quotation?

Please send us drawings in igs, dwg, step etc. together with detailed PDF.

If you have any requirements, please note, and we could provide professional advice for your reference.

Customer Inquiry →Engineering Meeting →Cost Analysis →Sales Analysis →Quote to Customer

1-3 Work Days Only

Submit RFQ with complete commercial terms

2, What if we do not have drawing?

Samples would be available, and we would send you drawing to confirm.

Of course, we would ensure the safety of the drawing.

3. How to pay?

For small quantity, we could provide T/T, T/T commission will be added to the order.

For the big one, T/T is preferred.

4. How to ship?

For small quantity, we have cooperation with DHL, FEDEX, UPS etc

For big quantity, air or sea would be available for you to choose.

1, 100% inspection before shipment.

2, Satisfied packing, carton, wooden case, pallet,or according to your requirement.

3, Samples are within 15 days after the receipt of the deposit. production will be finished about 30-40 days after samples confirma

| process | powder metallurgy |

| applied software | pro-e, CAD, PDF |

| material | iron alloy , stainless steel, copper. |

| surface finish | black, plating, PVD, polishing, sandblasting |

| tolerance precision | ±0.02~0.05mm |

| quality system | 100% inspection before shipment |

| dimensions | as per customer's requests |

| samples qty | 5-10 pcs(for free) |

| certification | ISO 9001, TS 16949, IECQQC080000 |

| packgae | plastic bag and carton or as customer's requests |

| lead time | base on the qty of order(usually 40-45 days) |

Previous :

Precision Metal Injection Molding Sintering Part MIM Electronic ComponentsNext :

Manufacture Powder MIM Parts for Headphone AccessoriesIf you have questions or suggestions, please leave us a message,we will reply you as soon as we can!

Copyright © 2010-2022 Harber mim-experts.com All Rights Reserved | Sitemap

Harber Metal firmly believes that quality is the soul of metal parts, and strictly abides by every standard, every process of production, and every detail of service!

Harber MIM, your total metal component solution

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.