Powder Metallurgy MIM technology Application in Jewelry

powder metallurgy MIM technology to achieve the production of shaped and complex structures of various types of parts.

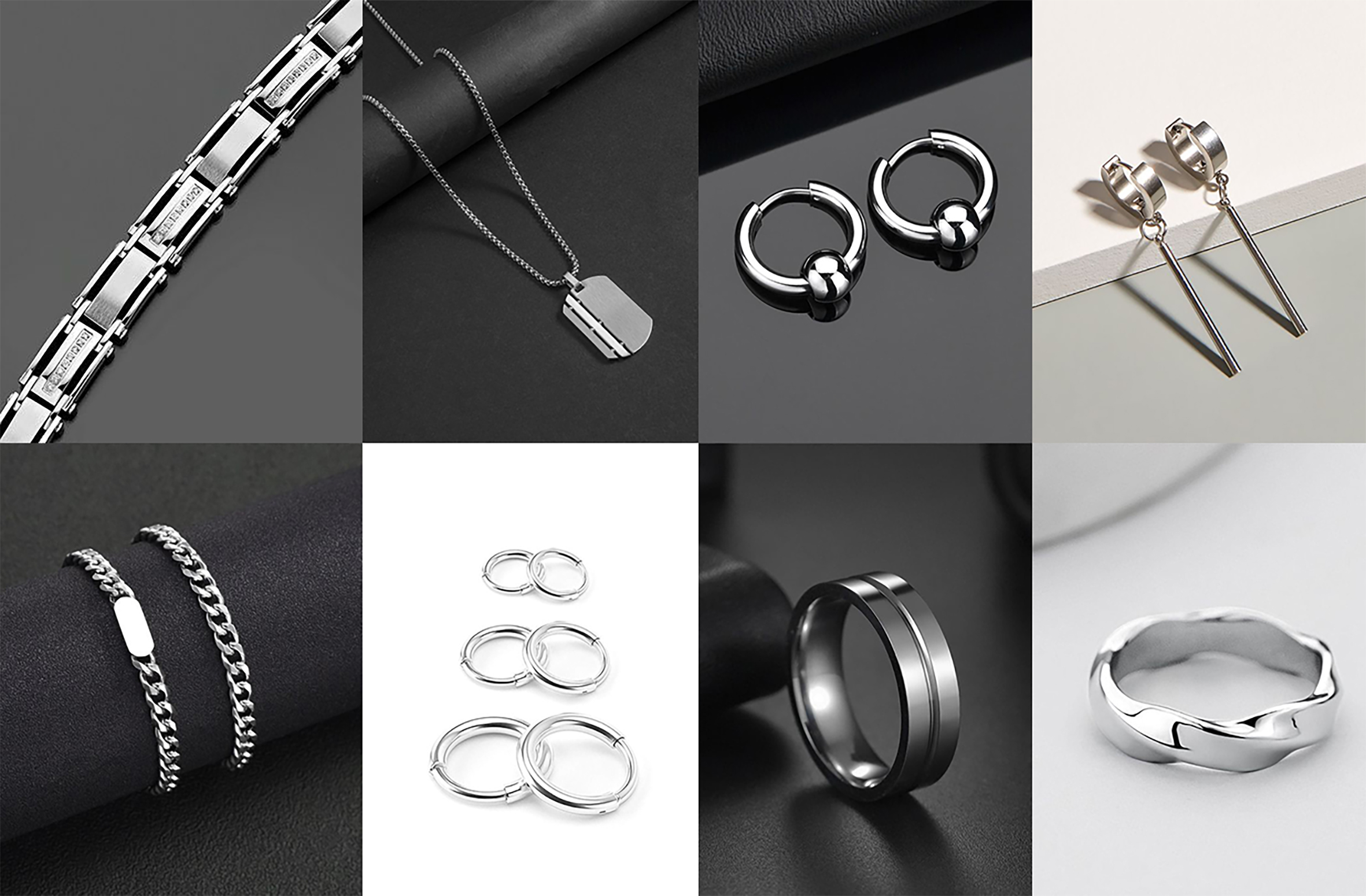

Stainless steel jewelry is now a new type of jewelry, its main features are not easy to rust and fade, and the price is relatively affordable, most customers who pursue style will choose this type of material to wear jewelry, and many brand merchants will choose powder metallurgy MIM technology to achieve the production of various parts with different shapes and complex structures in jewelry accessories. At present, the stainless steel jewelry market is gradually developing and growing, and has formed a certain scale. According to incomplete statistics, there are currently more than 1,000 enterprises engaged in stainless steel jewelry manufacturing and sales in China, most of which are small and medium-sized enterprises, while large enterprises are still rare.

Because stainless steel jewelry has the selling points of pure material, generous appearance, and moderate price, many young people or consumer groups are attracted. The stainless steel jewelry market is currently dominated by online sales, but there are also many offline stores selling it. These stores sell stainless steel jewelry with other types of jewelry, which are favored by many consumers.

The global stainless steel jewelry market sales reached about 90 billion yuan in 2023, and is expected to reach 150 billion yuan per year by 2028, with a compound annual growth rate (CAGR) of 1.2%. The global stainless steel jewelry manufacturers mainly include Swarovski, SPIKES, Huntmax, INOX Jewelry, Triton Jewelry, Alor, Bodyvibe and so on.

In recent years, the stainless steel jewelry market is expected to continue to maintain a rapid growth trend. On the one hand, due to the reasonable price of stainless steel jewelry, it meets the consumer demand of the public, and the market potential is very huge; on the other hand, with the continuous upgrading of consumer concepts and the improvement of health awareness of modern people, the material of jewelry has also received a lot of attention. The advantages of stainless steel jewelry, such as harmless and not easy to cause allergies, will be beneficial to its future development. At present, the market is accelerating the transformation to wholesale, branding and diversification. Manufacturers pay more attention to brand image building and brand creation; they enhance their core competitiveness by establishing brands, developing new products, improving product quality, strengthening after-sales service and other means. Therefore, stainless steel jewelry with rich and diverse varieties will gradually become the favorite in the market, and the production method of this kind of product is the core consideration of technology and cost.

It can realize the production of various kinds of special-shaped parts and complex parts, including the requirements of hardness, strength and corrosion resistance for products.

The sintered metal parts can be matched with various post-processing techniques, including MIM processing, shaping, machining, tapping, grinding, polishing, wire drawing, PVD (anti-corrosion and anti-sweat and fingerprint), etc., which can meet the design requirements of various jewelry wearables, achieve the best touch and visual effects.

The mass production standard of powder metallurgy MIM technology is the inevitable first choice among all processes. Various products within 1 to 50 grams are formed in one mold at a time, saving a lot of post-processing steps and completing batch production work on time according to customer requirements.

Powder metallurgy MIM technology can minimize alloy component segregation, eliminate coarse and uneven casting structure, and meet the uniformity of stainless steel jewelry.

It can easily realize various types of composites, give full play to the characteristics of each component material, and is a low-cost process technology for producing high-performance metal matrix composites.

According to customer's requirements for jewelry materials, it can make full use of ore, tailings, steelmaking sludge, rolling iron scales, recycled scrap metal as raw materials. It is a new technology that can effectively recycle and utilize materials.

It can process difficult-to-solubilize materials, greatly save metals, reduce product costs, and produce high-purity materials. It can ensure the correctness and uniformity of material composition ratio.

It can cooperate with other jewelry making tools and equipment, plate department process flow, lost wax casting (reverse mold) process flow, mold holding process, inlay process, electroplating process, foot gold process flow, machine cabinet processing technology, laser and rapid prototyping technology.

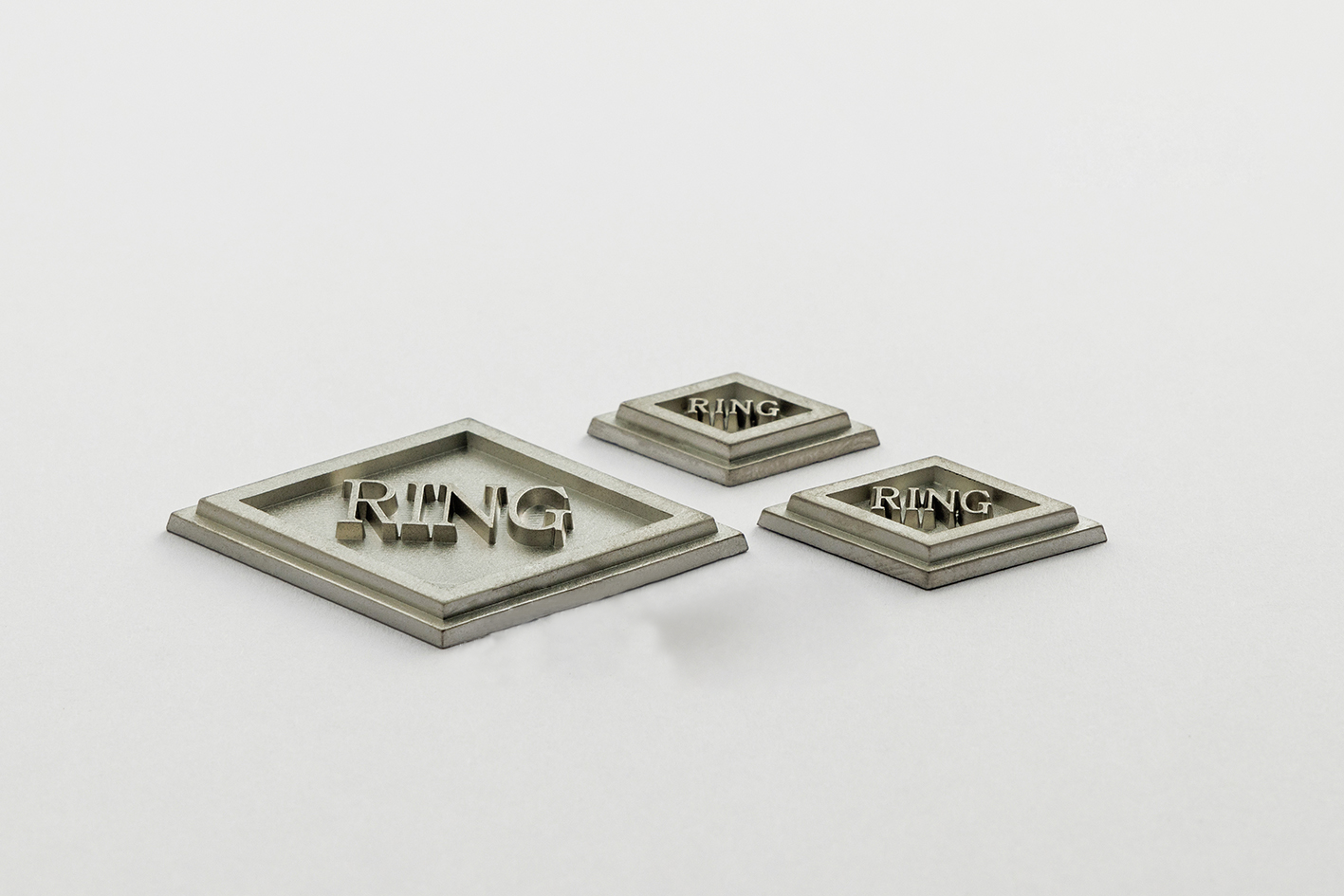

Customized MIM products for customers are for reference only (copyright belongs to customers)

Customized MIM products for customers are for reference only (copyright belongs to customers)

Customized MIM products for customers are for reference only (copyright belongs to customers)

Customized MIM products for customers are for reference only (copyright belongs to customers)

Customized MIM products for customers are for reference only (copyright belongs to customers)

Customized MIM products for customers are for reference only (copyright belongs to customers)

Harber Industrial Co., Ltd. is a powder metallurgy MIM manufacturer certified by ISO:9001 quality system. From drawings, molds to batch production one-stop service. Quality policy: win customers with quality, seek development with integrity, always pursue customer satisfaction.

Previous :

Powder Metallurgy MIM Watch ConnectorsNext :

无Copyright © 2010-2022 Harber mim-experts.com All Rights Reserved | Sitemap

Harber Metal firmly believes that quality is the soul of metal parts, and strictly abides by every standard, every process of production, and every detail of service!

Harber MIM, your total metal component solution

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.