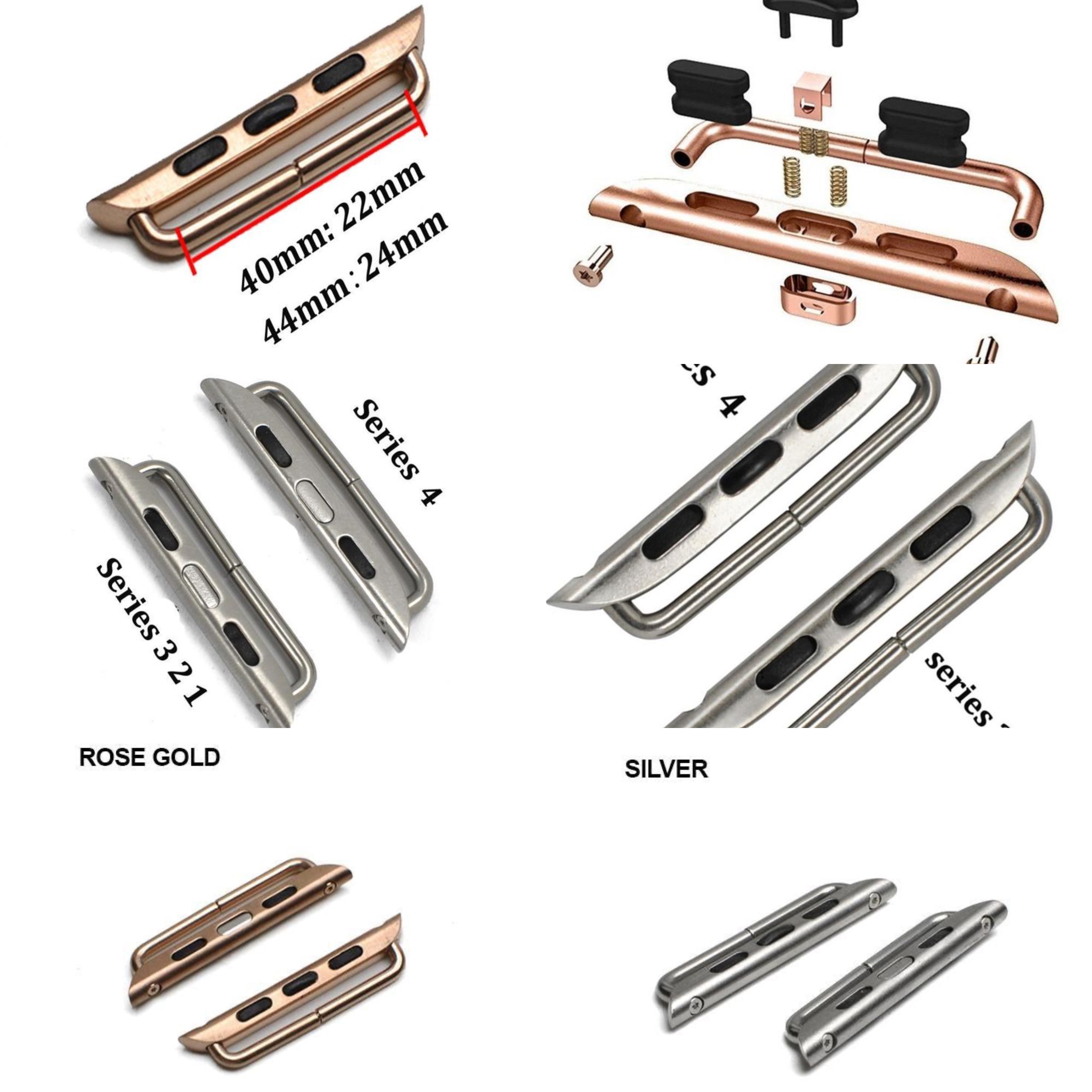

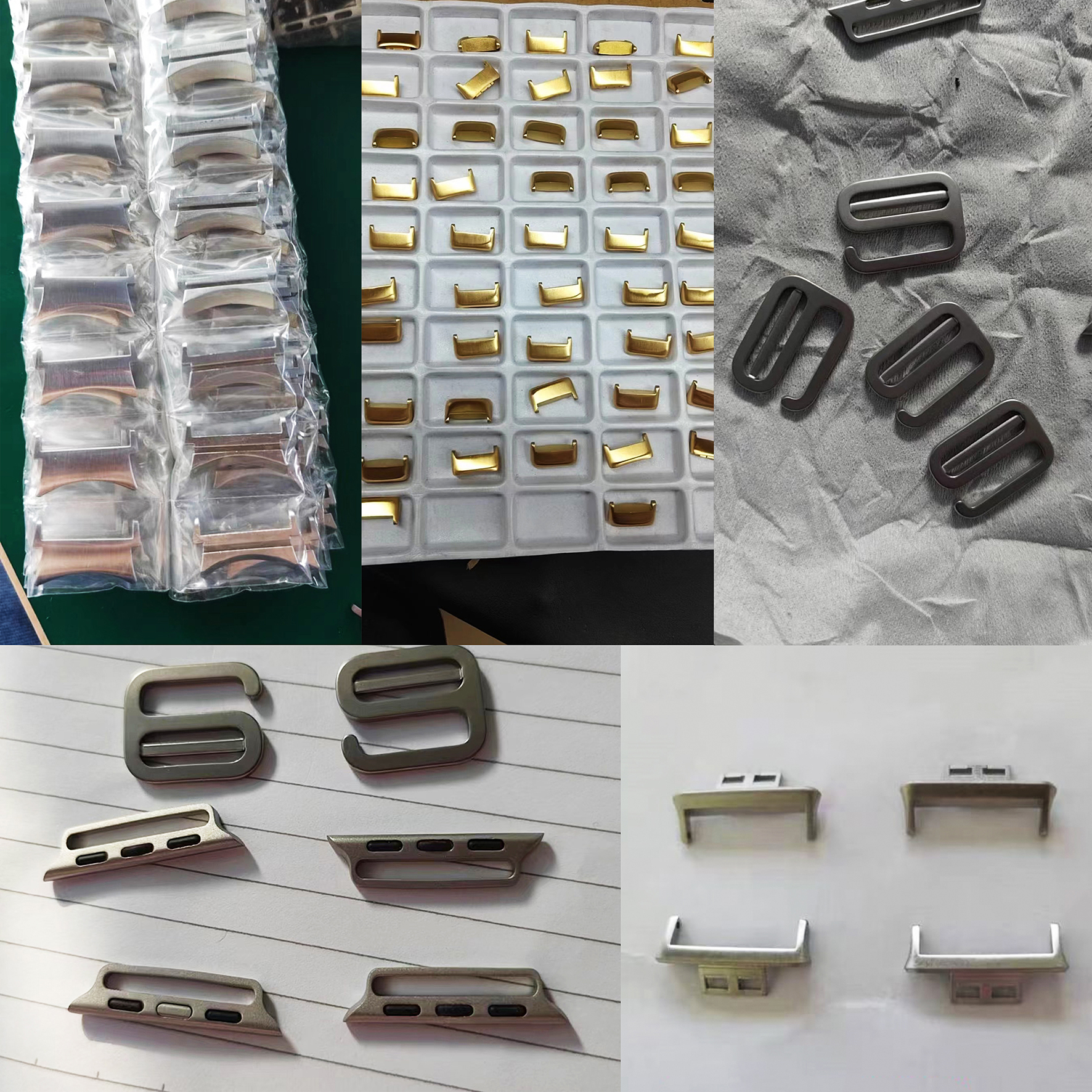

Powder Metallurgy MIM Watch Connectors

The shell with the connection structure is an important key part of the watch, which is the movable joint of the watch and a direction worthy of structural design. The traditional shell with the connection structure is to add a spring device on the connector (live ear) between the case and the strap, and push the live ear easily with tweezers to remove and replace the strap. At present, this traditional shell with the connection structure is widely used by well-known brands at home and abroad, and its characteristics are simple and few parts.

At present, the market demand is constantly updated, and wearers are not limited to wearing only one watch. The easy replaceability, color and material diversity of the watch strap are more important aspects for wearers. One watch with multiple straps has gradually become a new selling point in the market, and it is an important aspect for the watch design team of the clock and watch manufacturing industry to study.

In order to adapt to market demand, meet customer needs, and increase the attractiveness of watches, easy-to-remove shell with structures have corresponding design research in each clock and watch enterprise. In addition to Vacheron Constantin, Panerai and others, quick-release straps can be seen on other well-known brand watches. With the continuous improvement of domestic and foreign market demand for easy disassembly of watch case strap disassembly structure, combined with the rapid development of modern CNC technology and information technology, it is an inevitable trend to promote domestic and foreign clock and watch manufacturing enterprises to design more diversified case strap connection structures. The style and type of watches will continue to break through the existing number in the future.

At present, the varieties of powder metallurgy MIM materials in the market demand of watch wearing consumption are still mainly stainless steel, with a market share of 65%, low alloy steel accounting for about 23%, cobalt-based alloy 5%, tungsten-based alloy about 5%, titanium alloy 0.4%, and others are a small amount of copper and hard alloys. With the continuous improvement of diversified and lightweight product requirements in downstream fields, electronic parts materials are also developing in the direction of non-magnetic harmless (such as high-nitrogen nickel-free stainless steel, copper alloy, aluminum alloy) and composite materials (such as metal-ceramic, metal-plastic). Titanium and titanium alloys are also expected to become the next generation of star materials after stainless steel, and will be widely used in high-end fields such as automobiles, medical care, hardware, etc.; powder metallurgy MIM applications in watches are also widely visible.

The watches (or smart watches) we usually wear have bezels, dials, connectors, straps, etc., which are all made of powder metallurgy stainless steel materials.

Harber Industrial Ltd: specializes in producing various stainless steel connectors in powder metallurgy (MIM injection molding) process, including Samsung, Xiaomi, Huawei, oppo, Apple, Google and other various strap and stainless steel models;

Copyright © 2010-2022 Harber mim-experts.com All Rights Reserved | Sitemap

Harber Metal firmly believes that quality is the soul of metal parts, and strictly abides by every standard, every process of production, and every detail of service!

Harber MIM, your total metal component solution

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.