Harber’s expertise is in the area of overseas parts manufacturing, engineering, supply chain management, and cost control while eliminating liabilities and risks in the supply of critical parts.

Everything we do is guaranteed and expertly managed by our bilingual team in Ireland. We provide our clients access to guaranteed, economical solutions without compromising quality, service & visibility.

We give our clients the peace of mind to know that you have an Irish-based team to assist with your production needs step by step - with stress-free development, ordering, production and delivery.

Our clients have access to our premium overseas production facilities and highly competitive pricing. We remove the frustration, hassles, and headaches that overseas sourcing can often present for many companies. We save our clients time, money and provide them with world-class parts and service; we are your partner for parts, we are Harber.

ISO 9001 is an internationally recognised standard for Quality Assurance. For companies to achieve ISO 9001 certification they must demonstrate that not only are their products and services produced and delivered to high standards but also that all the supporting paperwork such as drawings, checklists, etc are in place and completed in order to verify the company has good controls around every step of its process.

The ability to communicate in Chinese on a daily basis.

Having qualified engineering and quality staff in China that are working directly for Harber with suppliers.

The ability to visit suppliers in China on a daily basis.

Ability to check parts prior to shipping.

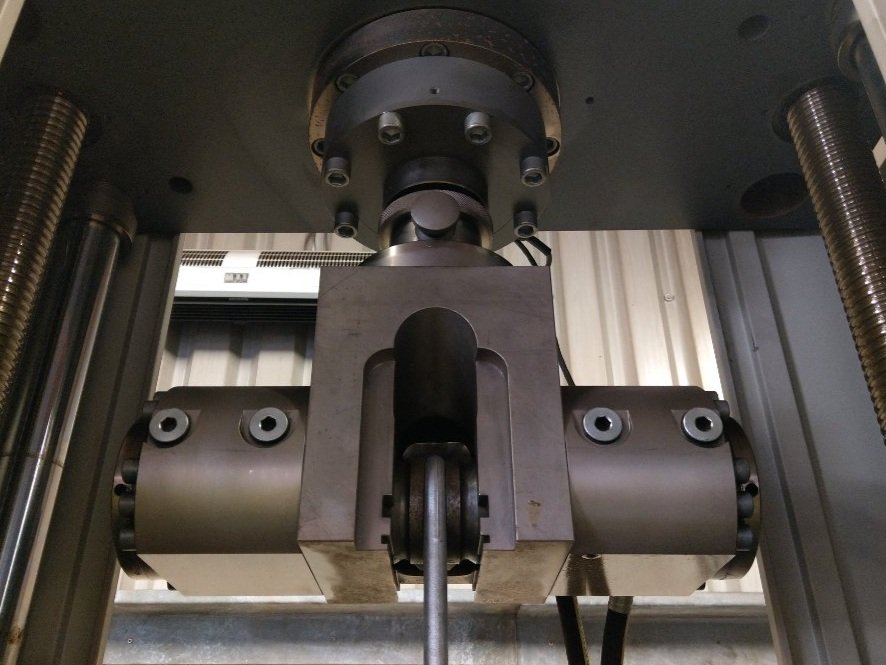

Ability to independently test parts in China.

The ability to project manage tools and prototypes in China.

No risk on quality and delivery from the far east.

Access to low-cost suppliers at normal office hours here in Europe.

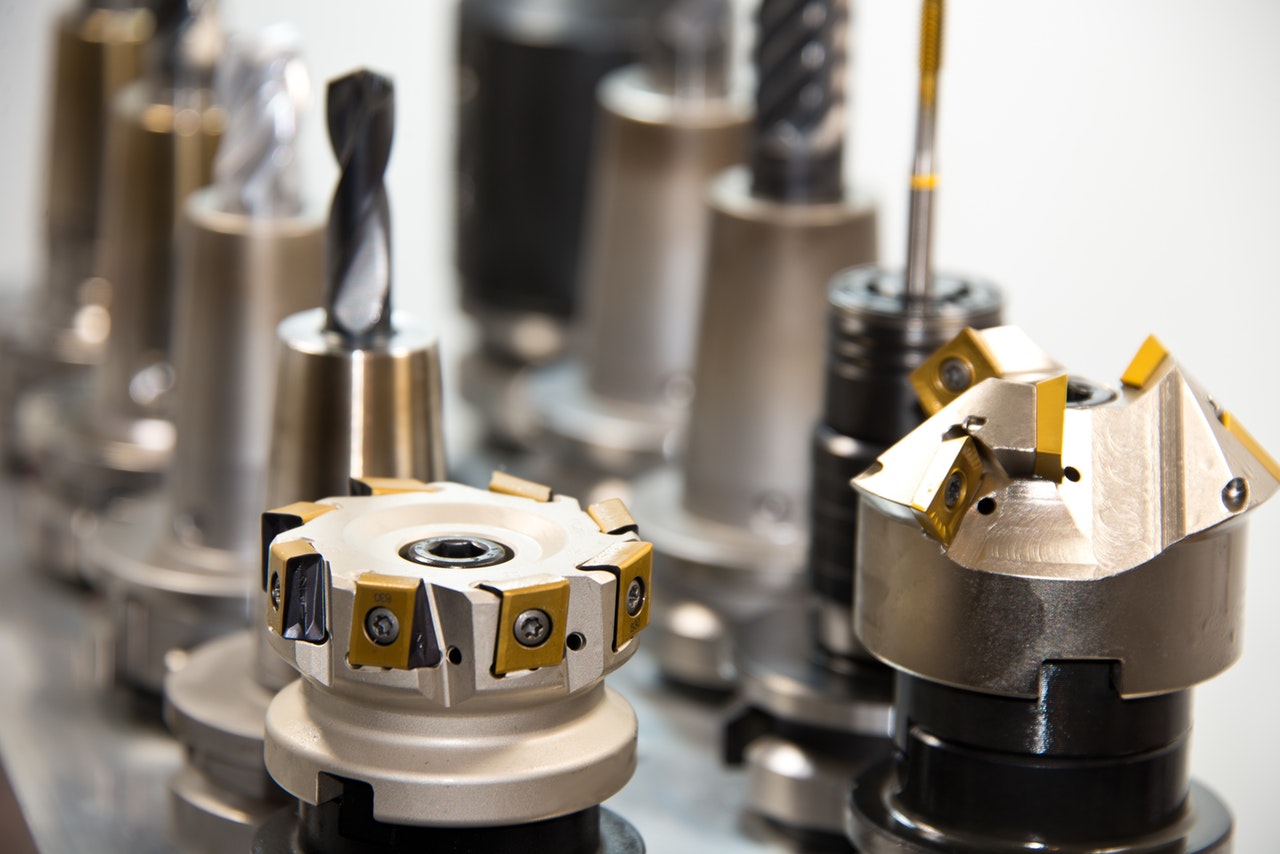

Complete management of custom parts from an engineering and supply point of view.

Harber Offer Full Traceability With All Shipments

✓ No Compromise In Quality, All Parts Checked Before Shipping.

✓ Dimensional Check Report.

✓ CMM Reports If Applicable.

✓ Production Data Reports If Applicable.

Testing Standards For Materials & Parts

✓ Mechanical Testing.

✓ Tensile Testing.

✓ Impact Testing.

✓ Implementation Of The Highest Production Standards, Quality Control Standards, Testing, NPI And Tooling.

Interpretation Of Quality And Engineering Standards

✓ Material Composition Certification From Steel Mill.

✓ Independent SGS Certification, If Required.

✓ Galvanising Thickness Testing, Zinc Analysis.

✓ Surface Measurement, Ra, Rz Etc.

✓ Gauge Check, Go/NoGo, Thread, Custom Etc.

About Harber

Hot Sale MIM Parts

Precision Metal Injection Molding Sintering Part MIM Medical Structural Parts Harber Industrial Precision Metal Injection Molding Sintering Part MIM Medical Structural Parts, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Precision Metal Injection Molding Sintering Medical Instrument Parts Harber Industrial Injection Molding Sintering Medical Instrument Parts, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Precision Metal Injection Molding Sintering Medical MIM Surgery Forceps Parts Harber Industrial Metal Injection Molding Sintering Medical MIM Surgery Forceps Parts, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Precision Metal Injection Molding Sintering Part MIM Medical Instrument Surgery Bipolar Forceps Harber Industrial Injection Molding Sintering Part MIM Medical Instrument Surgery Bipolar Forceps, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Precision Metal Injection Molding Sintering Part MIM Medical Accessories Harber Industrial Precision Metal Injection Molding Sintering Part MIM Medical Accessories, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Copyright © 2010-2022 Harber mim-experts.com All Rights Reserved | Sitemap

Harber Metal firmly believes that quality is the soul of metal parts, and strictly abides by every standard, every process of production, and every detail of service!

Harber MIM, your total metal component solution

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.