Harber MIM delivery the ripe experiences and solution through MIM process, MIM process has many advantages that other processes can not match. For example, the precision of products made by precision casting is not high, and the surface is very rough.

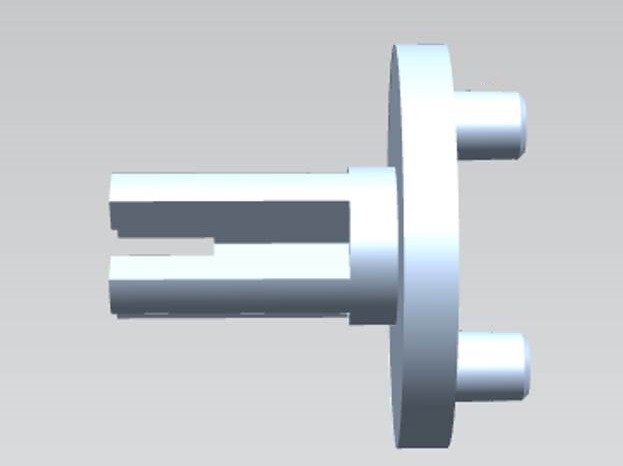

This is a part that one of our Polish customers needs to customize. Polish customer is one of our regular customer for 5 years. He ordered us 8 MIM parts at least here,including lock bolt, lock cylinder,door and window parts . This is a new project and need test many times.

This is a part that one of our China inland customers needs to customize. The customer is the top hardware assembly manufacturer in China, and has strict quality requirements. The material needed to be highly magnetic and corrosion resistant, hence the part had to go through various processes like surface coating electroless zinc nickel alloy.

This is a customer who makes household water valves in Guangdong Province, China. Before choosing us, he found many MIM factories. He wants to choose a supplier to provide products with high performance, high quality and appropriate price.

How to Calculate the Size of Outdoor LED Display How to Calculate the Size of Outdoor LED Display

We already had a customer who makes intelligent lock in Fenland and cooperated since year 2012. Until now, Harber had developed at leaset 50 kinds of lock parts for them,used material MIM4605, Fe4Ni, FeNi7, 304L and 316L.

Products Group

Hot Sale MIM Parts

Precision Metal Injection Molding Sintering Part MIM Medical Structural Parts Harber Industrial Precision Metal Injection Molding Sintering Part MIM Medical Structural Parts, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Precision Metal Injection Molding Sintering Medical Instrument Parts Harber Industrial Injection Molding Sintering Medical Instrument Parts, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Precision Metal Injection Molding Sintering Medical MIM Surgery Forceps Parts Harber Industrial Metal Injection Molding Sintering Medical MIM Surgery Forceps Parts, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Precision Metal Injection Molding Sintering Part MIM Medical Instrument Surgery Bipolar Forceps Harber Industrial Injection Molding Sintering Part MIM Medical Instrument Surgery Bipolar Forceps, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Precision Metal Injection Molding Sintering Part MIM Medical Accessories Harber Industrial Precision Metal Injection Molding Sintering Part MIM Medical Accessories, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Copyright © 2010-2022 Harber mim-experts.com All Rights Reserved | Sitemap

Harber Metal firmly believes that quality is the soul of metal parts, and strictly abides by every standard, every process of production, and every detail of service!

Harber MIM, your total metal component solution

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.